Must-Know Vocabulary and Concepts for Laser Engraving Machines (Beginner’s Guide)

Laser engraving unlocks detailed images, precise cuts, and fast personalization—but the vocabulary can feel intimidating. This guide explains the essential terms and concepts so you can dial in settings, avoid mistakes, and create with confidence.

In This Guide

- Why Vocabulary Matters

- Core Laser Terms

- Power & Speed

- Engraving Resolution

- Focus & Positioning

- Material Terms

- Software Concepts

- Beginner Pitfalls

- Quick Glossary

- Conclusion & Next Steps

Why Learning Laser Engraving Vocabulary Matters

A laser isn’t a plug-and-play printer. Results depend on the balance of power, speed, focus, and resolution. Learn these terms and you’ll understand tutorials, set materials correctly, and avoid avoidable waste.

- Follow guides without confusion.

- Choose settings for different materials confidently.

- Work safely and protect optics and mechanics.

Core Laser Engraving Terms

- Laser Module / Tube: The beam source. Diode lasers (5–20W) are common for desktops; CO₂ tubes (40W+) add cutting power. Power mainly affects cutting thickness, not engraving sharpness.

- Optics (Lens & Mirrors): Lenses focus the beam; CO₂ machines use mirrors to steer it. Clean optics are essential for consistent output.

- Beam Spot Size: Diameter of the focused beam. Smaller spots = finer detail but typically shallower cutting.

- Kerf: Width of material removed when cutting. Account for kerf in press-fit or interlocking designs.

- Air Assist: Directed airflow that clears smoke and debris, improving edge quality and reducing charring.

Photo Credit: Omtech

Power & Speed Concepts

Engraving and cutting are about applying the right energy to the material.

- Wattage (Power): Rated output of the module/tube. Higher wattage cuts thicker materials more easily.

- Percentage Power: Software setting that scales output. Many users run 60–80% to balance performance and tube/module life.

- Speed: Motion speed of the laser head. For cutting, slower speeds with higher power go deeper; for engraving, faster speeds with lower power prevent over-burn.

- Passes: Repeating the same path. Multiple moderate passes often yield cleaner edges than one scorched high-power pass.

Engraving Resolution Terms

Photo Credit: Epilog Laser

- DPI (Dots Per Inch): Engraving resolution. Higher isn’t always better—on wood, 300–400 DPI often looks cleaner than very high DPI that scorches.

- Line Interval / Scan Gap: Spacing between raster scan lines. Smaller gaps = smoother gradients but longer jobs.

- Raster Engraving: Back-and-forth scanning like printing; best for photos and shading.

- Vector Engraving: Follows paths (lines/curves); best for logos, text outlines, and precise marking.

Tip: Choose DPI based on material and art style. Photos can benefit from higher DPI; bold wood signage usually does not.

Focus & Positioning

- Focus: Adjust lens-to-material distance for the smallest spot. Poor focus widens kerf, weakens cuts, and blurs details.

- Z-Axis / Bed Height: Raise/lower the head or bed to focus when changing material thickness.

- Origin / Home: The job’s starting point. Set it consistently (commonly front-left/top) to align artwork with stock.

Material Terms

- Engravable: Wood (solid, ply, MDF), acrylic, leather, paper, cardboard, fabric, slate, glass, anodized/painted metals.

- Do Not Engrave: PVC/vinyl and some plastics release toxic chlorine; certain polycarbonates can produce harmful fumes. Always verify material safety.

- Masking / Protective Layer: Tape/film applied to reduce smoke stains—especially helpful for wood and acrylic.

Software Concepts

Photo Credit: Endurance Lasers

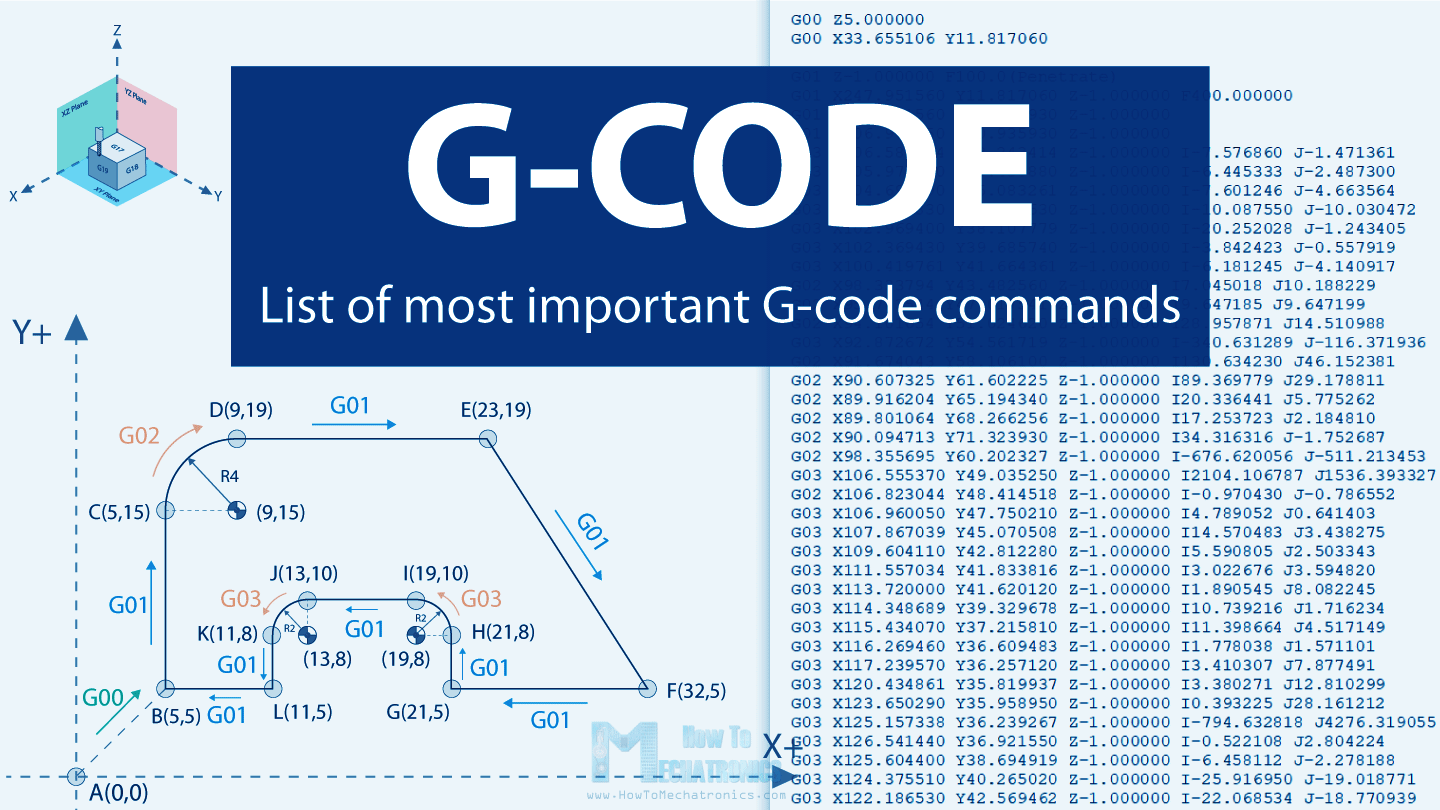

- G-code: Machine instructions that set motion, power, and timing.

- Controller Software: Sends jobs and controls the machine (e.g., LightBurn—paid, feature-rich; LaserGRBL—free, GRBL-friendly).

- Vector Files (SVG, DXF): Paths suited to cutting and outline engraving.

- Raster Files (PNG, JPG): Pixel images suited to photo/shaded engraving.

Typical workflow: Design → Toolpath/G-code → Send to machine.

Common Beginner Pitfalls (Vocabulary in Action)

- Overpowering thin stock: Use higher speed/lower power to avoid char and melt.

- Wrong focus height: Re-focus after any material thickness change.

- No air assist: Expect dirty edges and smoke marks without it.

- DPI confusion: DPI affects detail, not cut depth.

- Ignoring kerf: Account for beam width in press-fit joints and puzzle parts.

Quick Reference Glossary

| Term | Definition |

|---|---|

| Kerf | Width of material removed by the laser beam; critical for fit. |

| DPI | Dots per inch; controls engraving resolution and time. |

| Raster | Back-and-forth scanning for images and shading. |

| Vector | Path-following motion for outlines and cutting. |

| Air Assist | Airflow at the cut that clears smoke and reduces charring. |

| Focus | Lens-to-material distance adjusted for sharpest beam spot. |

| Passes | How many times the laser repeats the same toolpath. |

| Masking | Tape/film to protect surfaces from smoke stains. |

Conclusion & Next Steps

Mastering terms like kerf, DPI, raster vs vector, air assist, and focus turns trial-and-error into repeatable results. Use this glossary as a reference while you dial in materials and artwork.